聯系人:袁先生

座機:0769-82855009

手機:18002915910

郵箱:[email protected]

地址:東莞市長安鎮錦廈社區S358省道太安路263號(即德愛小學公交站臺旁)

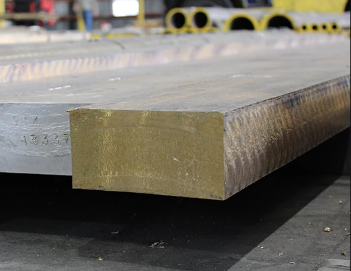

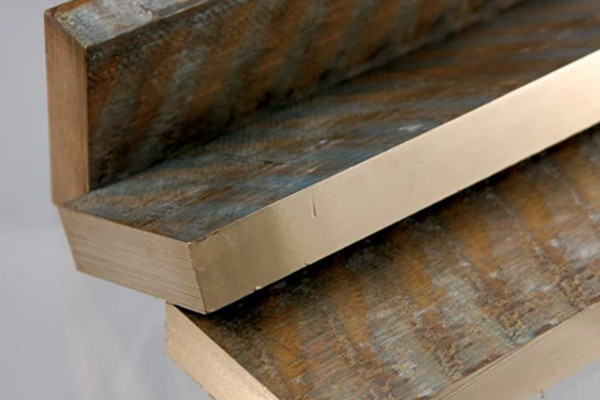

AMS-4598

特性:

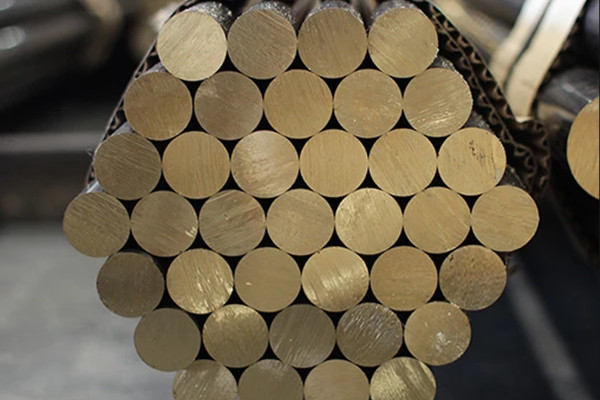

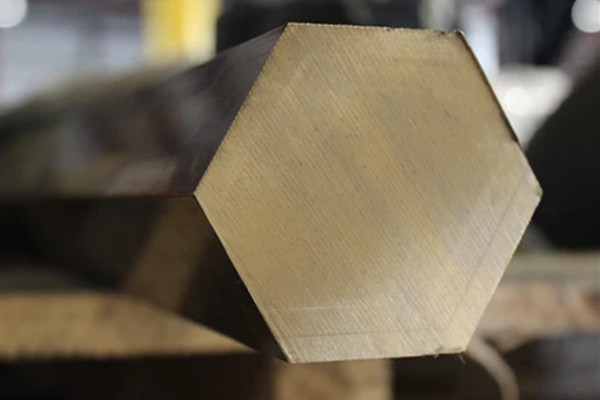

1、高的強度、彈性、耐磨性和抗磁性,在熱態和冷態壓力下加工性良好

2、頂極的機械性能、力學性能入加工性能

應用:

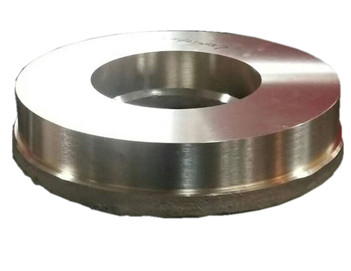

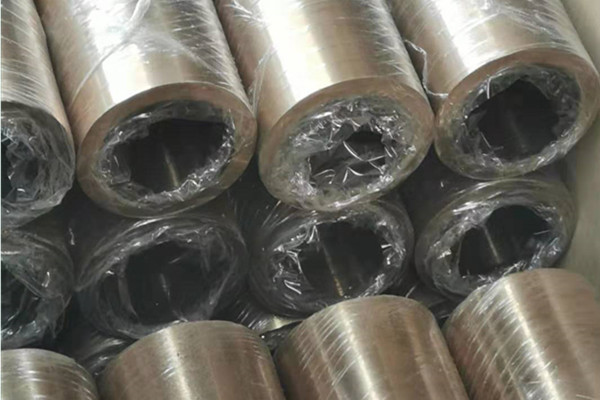

1、主要用于制作彈性元件和耐磨零件

2、機械、模具內部耐磨件及軸套

3、高鐵、船舶、飛機內部耐磨件

Technical Data Sheet

Copper alloy NO:AMS-4598

Solution annealed –TX&00

Chemical composition:

|

FE(iron)

|

SN(Tin) |

ZN(Zinc) |

NI(Nickel) |

MN(Manganese) |

CU(Copper) |

|

0.5-0.8

|

7.5-8.5 |

≤0.5 |

14.5-15.5 |

0.3 |

balance |

Mechanical and physical properties:

|

properties

|

Density ρ |

Tensile strength Rm |

Tensile strength Rm |

Electrical conductivity |

Elongation A5 |

Hardness |

Thermal conductivity λ |

|

Units

|

g∕cm3 |

MPa |

MPa |

% I.A.C.S |

% |

HRB |

W∕m.K |

|

Nominal Values

|

717-903 |

717-903 |

745-896 |

7.23-8.16 |

5-8 |

95-102 |

32-48 |

APPLICATIONS:

AMS 4598A was initially developed as an aircraft specification alloy for gears in retractable landing assemblies, engine spacer bearings and other similar applications. It is rapidly growing in use where higher mechanical properties at elevated temperatures together with corrosion-resistant properties are required.